Safety through technology: our test procedures at a glance

Magnetization, testing, and demagnetization – comprehensive solutions from one provider!

Safety through technology: our test procedures at a glance

Magnetization, testing, and demagnetization – comprehensive solutions from one provider!

Mobiel testing devices

MT testing and demagnetization – even in challenging and inaccessible areas

Compact, mobile testing devices provide significant advantages for on-site surface crack inspections. They enable technicians to efficiently test components in various hard-to-reach locations and ensure effective demagnetization.

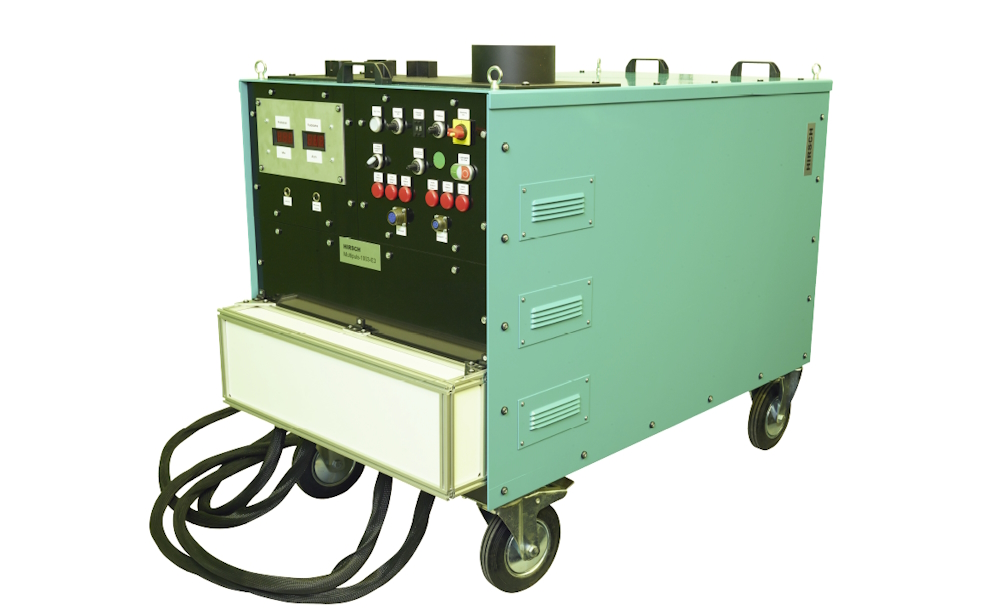

Our compact testing devices, weighing just 10 to 20 kg, deliver peak currents of up to 8,000 A while operating on a standard 230 V power supply. Depending on sheet thickness, they can cover mobile test areas of up to 2 m². Designed with a two-housing structure, these portable units are ideal for MT testing and demagnetization in confined spaces and containers, ensuring compliance with accident prevention regulations (UVV). The power supply and testing unit are housed separately for enhanced safety and ease of use.

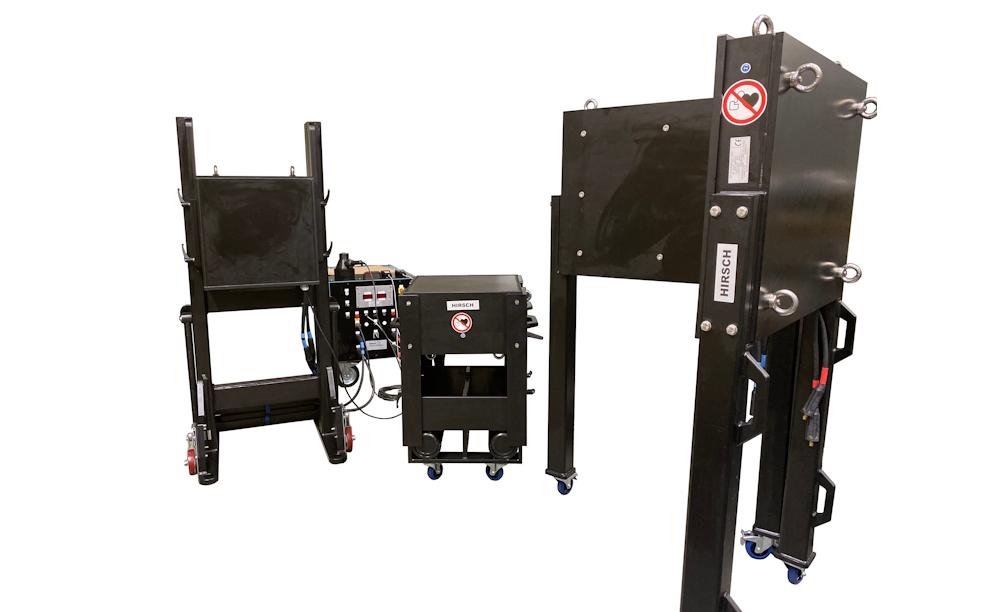

Even our most powerful devices, delivering currents of up to 3 x 30,000 A, are designed for mobility. Housed in compact, wheeled enclosures, they can be easily transported by hand, lifted, or moved with a forklift, enabling flexible on-site use.

Stationary testing devices

MT testing and demagnetization for complex component geometries

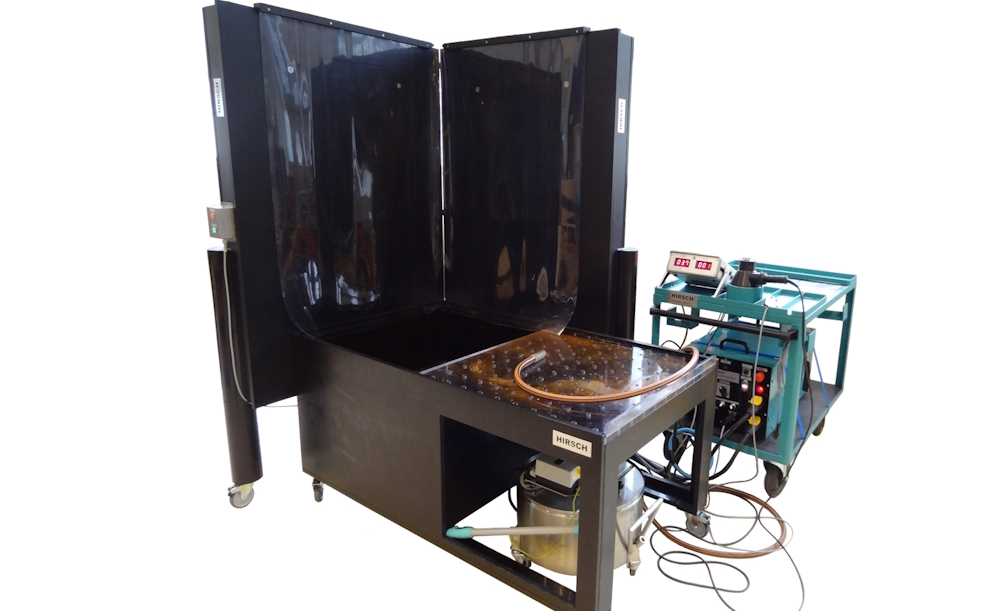

Stationary testing devices enable reliable MT testing and demagnetization of various steel components in a fixed setup. Depending on the application, DC and alternating pulse technology offer advanced methods for enhanced testing and demagnetization capabilities.

In the non-contact method, test magnetic fields are generated by two coils arranged at an angle or crossed, then introduced into the component. Stray fields emerging at surface cracks cause a precise accumulation of magnetic powder particles in the test fluid, resulting in sharp and clearly defined crack indications.

We apply this principle in the design of MT test tables, enabling the simultaneous testing of multiple compact components for both longitudinal and transverse defects.

We also provide MT testing systems integrated with a corner coil. This technology provides the rapid and cost-effective, contact-free testing and demagnetization of gears ranging from just a few millimeters to over 10 meters in outer diameter.

Measuring devices and accessories

Pulse test currents, pulse test field strength and residual field strength

The testing devices from HPT Hirsch Prüftechnik GmbH capture critical values for magnetic particle testing and demagnetization. These devices establish precise, inertia-free, and induction-free measurement of pulse test current strength, pulse field strength, and residual field strength.

We also provide the ideal accessories for all measuring and testing devices.

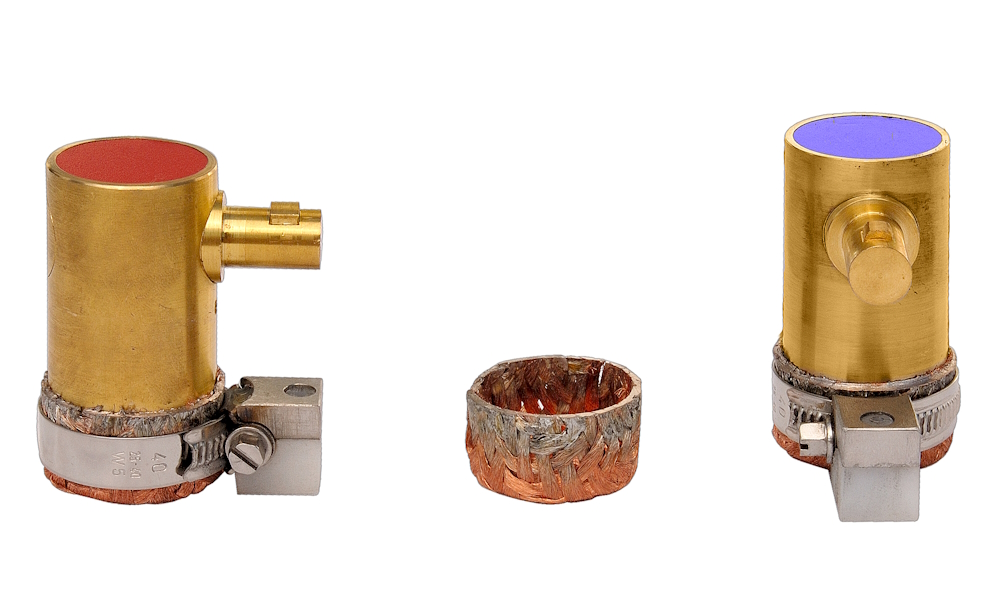

Magnetic poles for MT testing with current flow

UV test light with white-light superimposition

UV LED light for the detection of fluorescent crack indications

All required test, demagnetization and connection cables

angepasst auf die jeweilige Prüf- bzw. EntmagnetisierungsaufgabeCertificates from independent calibration laboratories forall our measuring devices

Data sheets

You can download all information about our appliances and accessories as a PDF.

Accessories:

01

Multipuls-1001-m

Testing device for pulse test currents, pulse test field and residual field strength

02

Multipuls-1001-mp

Magnetic poles/magnetic contacts for MT testing with current flow

03

Multipuls-1003-uv-led

UV LED light for the detection of fluorescent crack indications

MT-Prüfung

Testing and demagnetization devices:

MT testing and demagnetization of small to medium-sized components:

MT testing and demagnetization of small to large components:

06

Multipuls-1003-c1

Test current up to 8,000 A.

07

Multipuls-1003-e1

Test current up to 20,000 A.

Testing and demagnetization devices:

MT testing and demagnetization for components of all sizes, from small to extremely large.

08

Multipuls-1003-e2-1

Test current up to 30,000 A.

09

Multipuls-1003-e2-2

Test current up to 30,000 A. MT test and measuring device combined in a mobile housing.

MT-Prüf- und Messgerät in einem mobilen Gehäuse kombiniert.

10

Multipuls-1003-e2-3

Test current up to 30,000 A. MT test and measuring device combined in a mobile housing.

A mobile unit combining MT testing and measuring capabilities, featuring advanced AC pulse technology.

11

Multipuls-1003-e3

Test current up to 3 x 30,000 A. A mobile unit integrating MT testing and measurement capabilities.